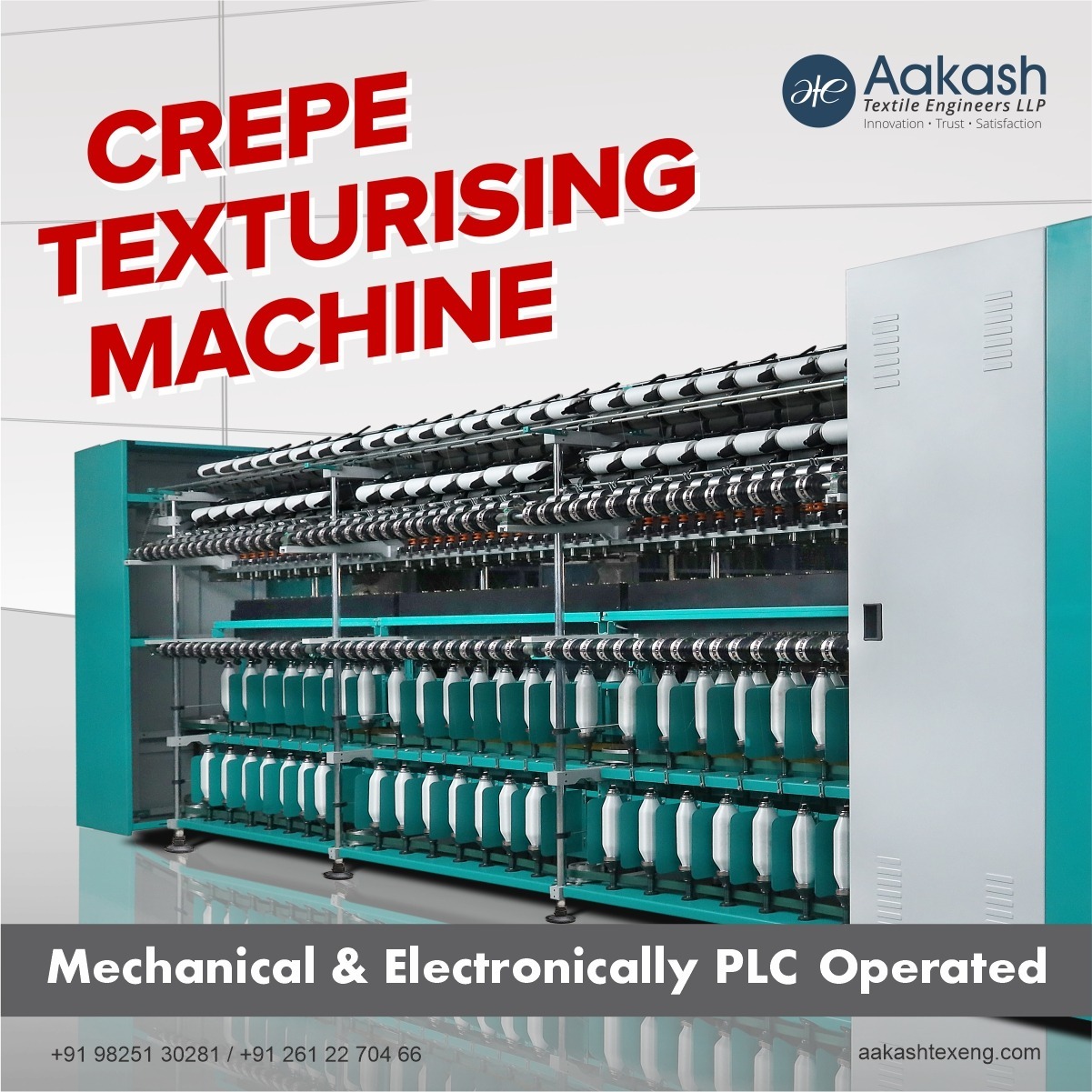

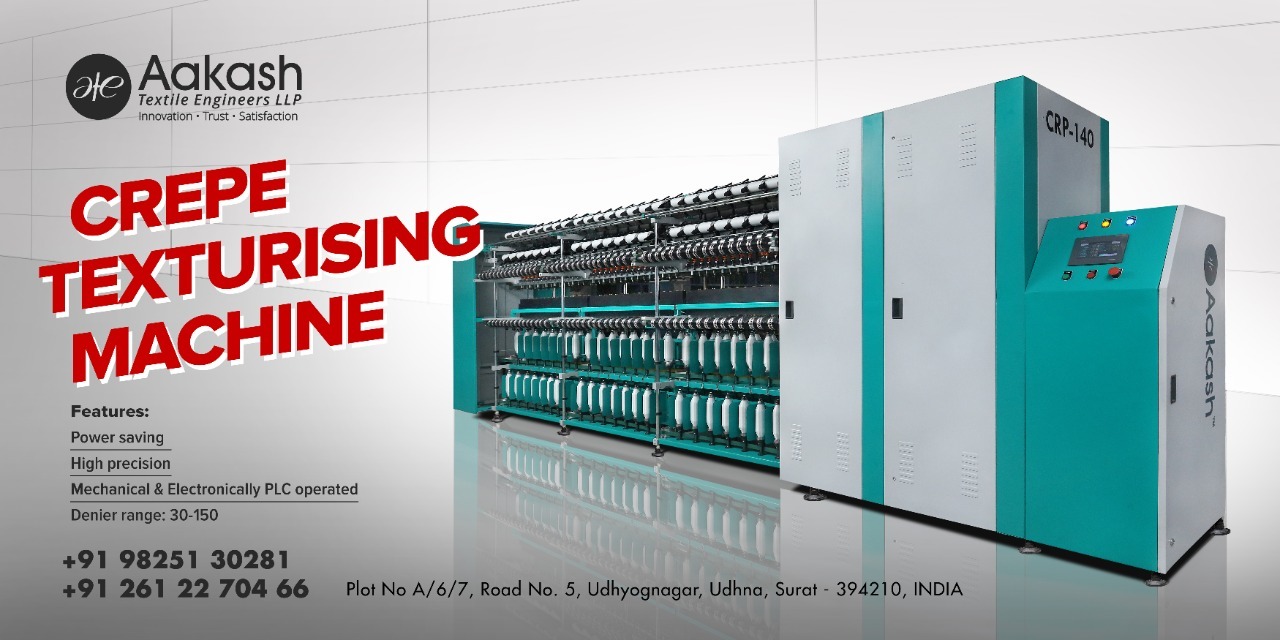

Crepe Texturising Machine

2000000 INR/Unit

Product Details:

- Frequency 50 Hertz (HZ)

- Product Type Textile Machinery

- Material Mild steel

- Machinery Type Crepe Texturising Machine

- Voltage 220/440 Volt (v)

- Click to View more

X

Crepe Texturising Machine Price And Quantity

- 2000000 INR/Unit

- 1 Unit

Crepe Texturising Machine Product Specifications

- 220/440 Volt (v)

- Crepe Texturising Machine

- 50 Hertz (HZ)

- Textile Machinery

- Mild steel

Crepe Texturising Machine Trade Information

- Cash Advance (CA), Cash in Advance (CID)

- Asia, Australia, South America, Eastern Europe

- , All India, South India, Central India, West India, North India, East India, Gujarat, Karnataka, Kerala, Lakshadweep, Mizoram, Meghalaya, Manipur, Andhra Pradesh, Bihar, Chandigarh, Daman and Diu, Goa, Jharkhand, Odisha, Punjab, Assam, Delhi, Dadra and Nagar Haveli, Andaman and Nicobar Islands, Arunachal Pradesh, Chhattisgarh, Haryana, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Maharashtra, Nagaland, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Pondicherry, Uttar Pradesh, Uttarakhand, West Bengal

Product Description

The textile sector uses this Crepe Texturising Machine to provide textiles with a crepe or crinkled feel. As a result of the machine's employing multiple mechanical processes that modify the shape and look of textiles, the resulting final textile goods have characteristic textured patterns that can be both aesthetically pleasing and functional. Crepe, georgette, and various other fabrics that are frequently employed in clothing, household textiles, and various other applications are produced with this crepe texturising machine.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese